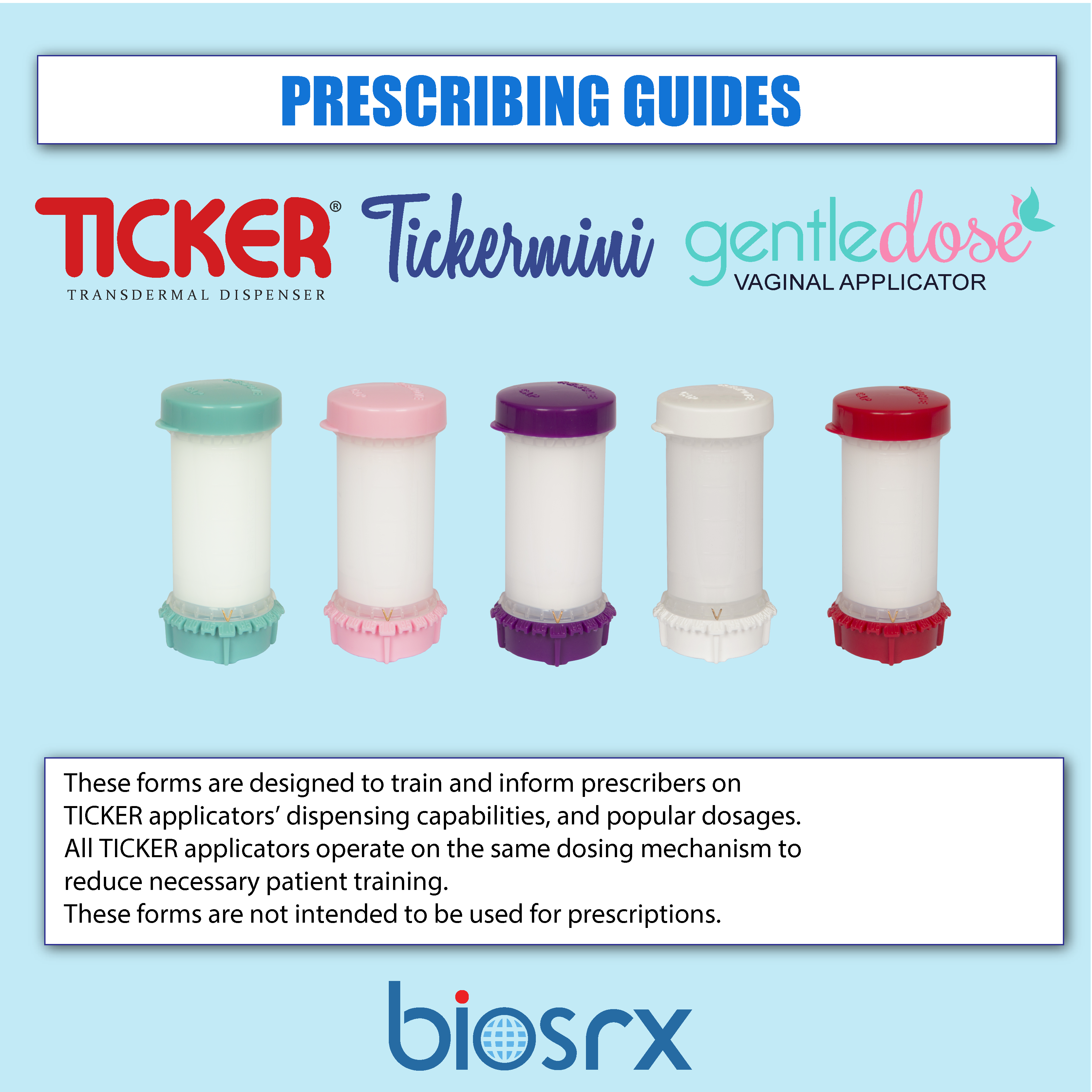

TICKER®

CHOOSE PATIENT BENEFITS

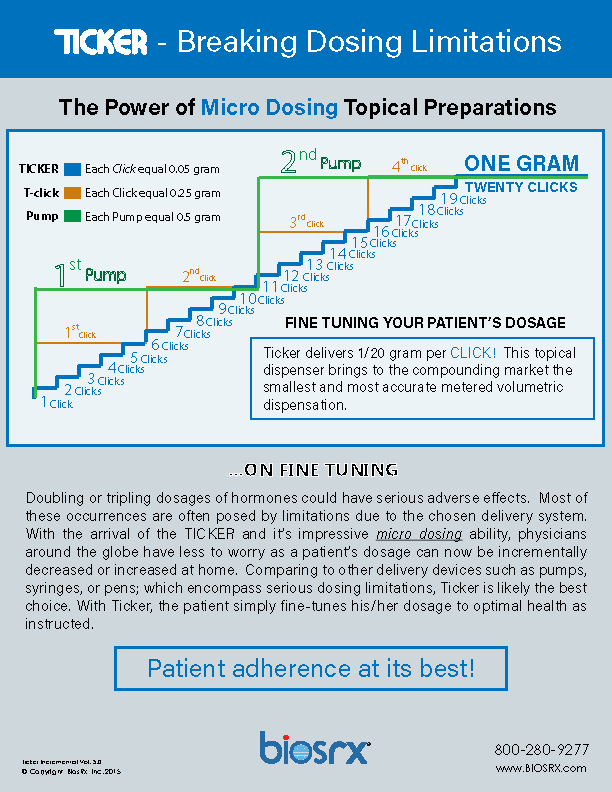

TICKER® is an easy-to-use topical applicator that dispenses practically every dose ever prescribed! As a clinical tool, TICKER offers prescribers more dosing options than other outdated dispensers.

Dispensing 1/20th milliliter with each click, TICKER® is the only metered applicator that can dispense any dose. You can now prescribe any dose your patient needs, without being limited by the pharmacy's applicator. Your patients won't have to change applicators as you optimize their dose, reducing patient training and confusion.

FINE-TUNING TOPICAL DOSAGES HAS NEVER BEEN EASIER

Mis-dosing, doubling, or tripling dosages of hormones could obviously have serious adverse effects to the health of your patients. Most of these occurrences are often posed by limitations due to the chosen delivery system, such as syringes that are difficult for elderly patients to use, or metered applicators that are limited in dose. With the arrival of TICKER applicator and itsmicro-dosing ability, physicians across North America and beyond have less to worry as a patient’s dosage can now be incrementally decreased or increased by the patient at home. With TICKER the patient simply fine-tunes their dosage to optimal health as instructed. Patient adherence at its best!